Certainly, here is a basic operating manual for a rebound test hammer, commonly used for non-destructive testing of concrete structures:

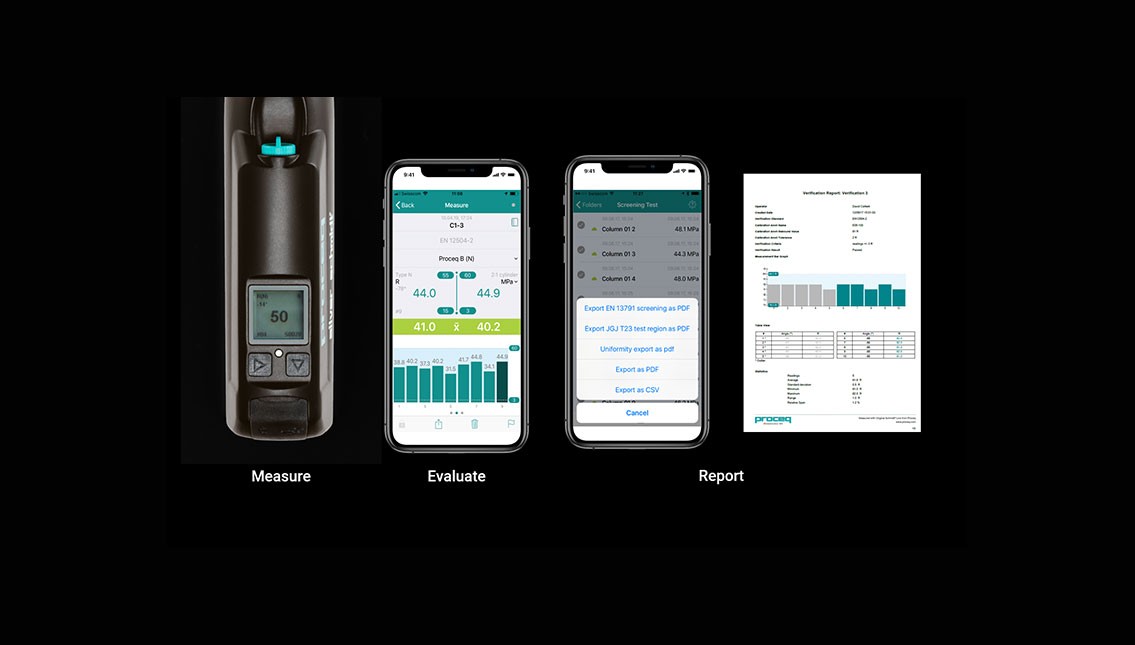

New Advance Model Proceq Silver Schmidt OS8200 Operating Manual

1. Introduction: The rebound test hammer is a portable device used to assess the surface hardness and, indirectly, the compressive strength of concrete structures. This test is non-destructive and widely employed in construction and civil engineering for quality control and structural assessment.

2. Safety Precautions:

- Always wear appropriate personal protective equipment, including safety glasses and gloves.

- Ensure a safe distance from other workers during testing to prevent accidents.

- Handle the rebound test hammer with care to avoid damage to the instrument or injury to the operator.

3. Equipment Setup:

- Ensure the rebound test hammer is in good working condition and calibrated regularly.

- Adjust the instrument’s impact energy, typically indicated as “N” for normal and “L” for low. Select the appropriate setting based on the expected strength of the concrete.

- Ensure that the hammer’s plunger and the concrete surface are clean and free from loose particles or debris.

4. Test Procedure: Follow these steps to perform a rebound test:

a. Hold the rebound test hammer firmly with one hand, making sure not to touch the plunger during testing.

b. Position the instrument perpendicular to the concrete surface at the location to be tested. Ensure the plunger makes direct contact with the surface.

c. Apply a firm, quick, and consistent force to the instrument’s trigger with your other hand. This causes the plunger to impact the concrete surface.

d. After impact, the rebound test hammer will rebound off the surface. Observe and record the rebound distance (R) indicated by the scale on the instrument. This scale typically ranges from 10 to 100, with higher values indicating higher concrete hardness.

e. Repeat the test at multiple locations to obtain a representative assessment of the concrete hardness.

5. Interpretation of Results: The rebound distance (R) obtained from the instrument needs to be correlated with the compressive strength of the concrete. This correlation can be established using calibration curves provided by the manufacturer or local standards.

6. Maintenance:

- Clean the instrument after each use to prevent debris from affecting future measurements.

- Periodically calibrate the rebound test hammer according to the manufacturer’s recommendations.

- Inspect the instrument for any damage or wear, particularly the plunger and the rebound scale.

7. Reporting: Record the rebound values obtained during testing and correlate them with the concrete’s compressive strength. Include all relevant details such as test locations and any anomalies observed during testing.

Always refer to the specific manufacturer’s instructions for your rebound test hammer, as operating procedures may vary slightly between models. Proper maintenance and calibration are essential to ensure accurate and reliable results in concrete hardness assessments.