Plate Load Test Apparatus or Plate Bearing Test Apparatus VSLIC-S173

short info

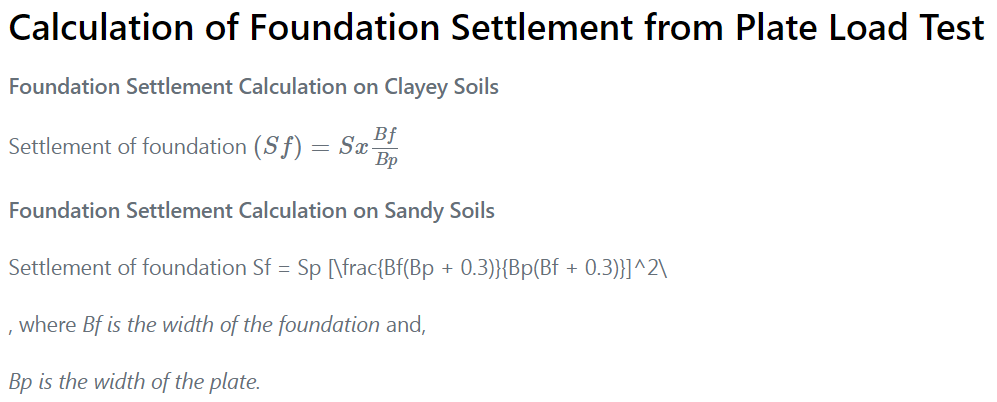

The Plate Load Test Apparatus this test is carried out to determine the bearing capacity of the ground on Road Structures, Road foundations, Road Infrastructures, Airport and Highway Pavements. The plate bearing test is essentially a model test of foundations which projects the stress and strain characteristics for evaluating the ultimate bearing capacity of foundations. This technique is a standard one for estimating the bearing value of soil in-situ. The results of other methods are always compared with the values obtained by the plate load test. In this method, a steel plate of a certain dimension is subjected to gradually increasing loads and the corresponding settlement is noted. The ultimate bearing capacity is taken as the load at which the plate starts sinking continuously at a rapid rate.

Standard

Model

Origin

Make/ OEM

Brochure