Digital Los Angeles Abrasion Testing Machine VSLIC-A118

short info

Digital Los Angeles Abrasion Machine is used for the determination of aggregates resistance to fragmentation.

Standard

Model

Origin

Make/ OEM

short info

Digital Los Angeles Abrasion Machine is used for the determination of aggregates resistance to fragmentation.

Standard

Model

Origin

Make/ OEM

There is also a Los Angeles Abrasion Device with Soundproof Safety Cabinet. In accordance with CE safety directive, it is made of steel and internally covered with sound insulation material for sound insulation. When the cabinet door is opened while the appliance is running, a micro switch automatically stops the drum from rotating.

The Locking Mechanism is also available on request (must be installed at the factory) and must be ordered separately. The locking mechanism assists the user when filling the samples and locking the door.

Abrasion Balls must be ordered separately according to the standards.

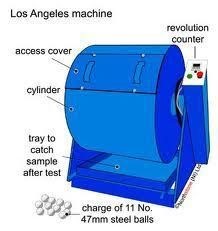

The machine consists of an electronic control unit and a rolled steel drum having an inside diameter of (711 ± 5) mm and internal length (508 ± 5) mm. The drum is rotated at a speed of between 31 and 33 r.p.m. Thanks to the rev counter, the motor stops by rotating the set number. It has a tray to collect the material and ball load after the experiment.

Los Angeles Features

Why we test abrasion value of coarse aggregates ?

The abrasion value of the aggregates is determined in order to determine their Resistance against wearing. In this the aggregate sample is mixed with abrasive charge consisting standard balls & rotated in closed inclined cylinders for specific number of revolutions.

Apparatus Required for the Test:

IS code for aggregate abrasion value test :-

Procedure of the Test

Tabular Column

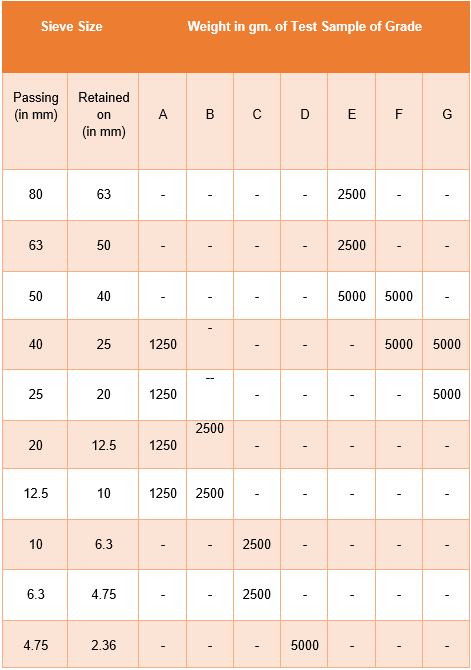

Table:- Specified Abrasive Charge

| Grading | Number of Spheres | Weight of Charge (g) |

| A | 12 | 5000 土 25 |

| B | 11 | 4584 土 25 |

| C | 8 | 3330 土 20 |

| D | 6 | 2500 土 15 |

| E | 12 | 5000 土 25 |

| F | 12 | 5000 土 25 |

| G | 12 | 5000 土 25 |

|

| Gradings of Test Samples |

OBSERVATIONS :–

| Trail 1 | Trail 2 | |

| Total weight of dry sample taken= W1 g | ||

| Weight of portion passing 1.7 mm sieve= W2 g | ||

| Aggregate abrasion value = (W2/W1) x 100(%) |

|

| Los Angeles Abrasion Testing Machine |

RESULT :-

Mean Los Angeles Abrasion value =………… %