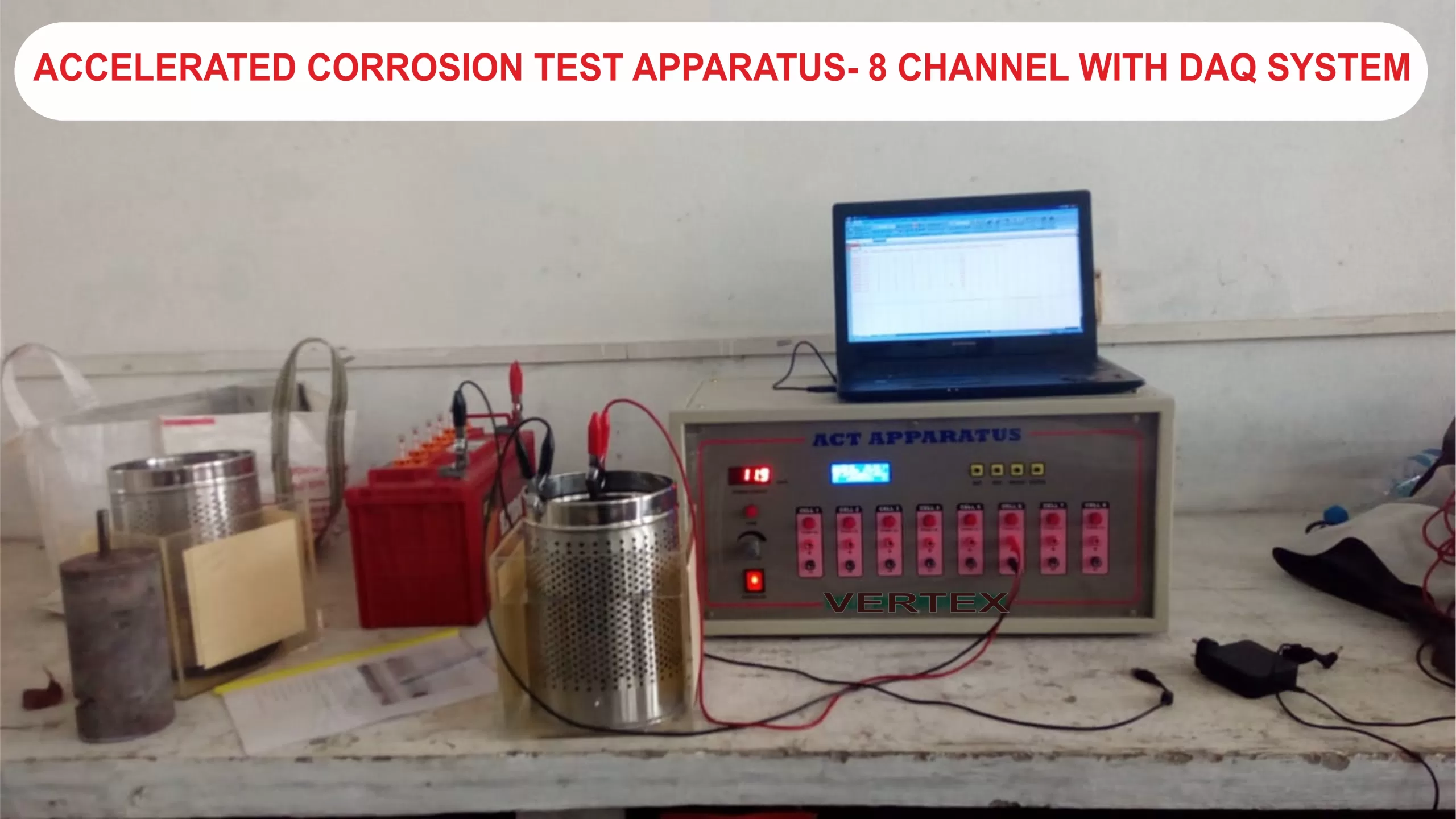

Accelerated Corrosion Test Apparatus- 8 Channel with DAQ Software VSLIC-C258

short info

- The DC power supply for all the 8 cells 0 to 12 volt continuously.

- The DC supply is provided to all the three channels and the current of individual cells are monitored continuously.

- Each channel is provided with protective fuse.

- Flexible cables with banana type pins are provided for all the cells for easier connections to the ACPT apparatus.

- DC voltage is controlled by continuously adjustable potentiometer

- Power input: 230 volt 50Hz AC

- Battery backup: 12v 75AH batteries x 6Nos connected in series.